Digital Dentures

Ivoclar Digital Dentures

Ivoclar Digital Dentures are a complete manufacturing process for the rapid production of removable full-arch dentures. This innovative process integrates the treatment steps in the dental practice with the digital

manufacturing processes in the lab. Exclusive design software and ideally coordinated materials, combined with well-designed manufacturing strategies and the cutting-edge PrograMill milling equipment platform, provide predictable and reproducible results.

Read More

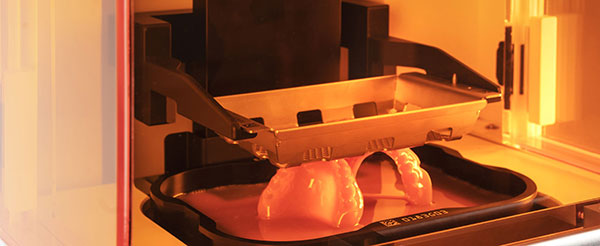

3D Printed Digital Dentures

Modern dentures are made from acrylic resin and other plastics. The time-consuming and labor-intensive analog workflow involves multiple patient visits and production steps. Digital denture workflows are on the rise, along with traditional dentures, digital dentures can be easily implemented into your line of restorative options for patients.

Read More

Using design software and 3D printing to manufacture dentures provides several instant advantages:

- Low-cost production

- Accurate, consistent, high-quality results

- Intuitive, adaptable tools

- Simplified, fast duplications

- Truly custom teeth

- Save Time

Today’s digital denture workflow begins after the laboratory pours and articulates the wax-rim and final model. A technician digitizes the model and wax-rim with a desktop 3D scanner, then designs the denture digitally and 3D prints a try-in or the final denture.

Contact Us

- Toll Free: (877) 528-2522

- Local: (951) 699-0435

- Fax: (951) 699-2226

- Email Nash Dental Lab